Want to find out more? Watch below!

Some of the names we’re proud to work with

Our history

CastAlum is an internationally acclaimed aluminium die casting and machining centre located in Welshpool, UK. The site was a Greenfield development in the winter of 2000-2001, serving one customer only.

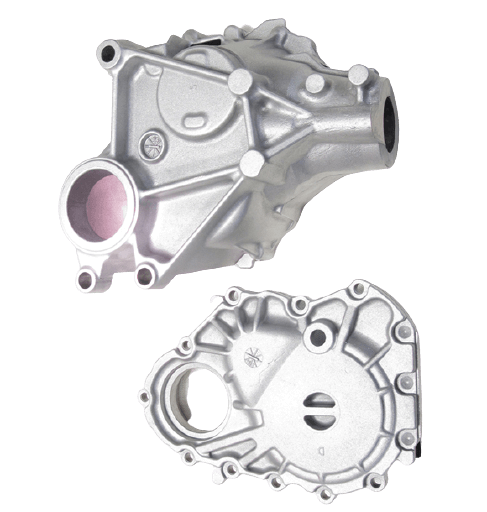

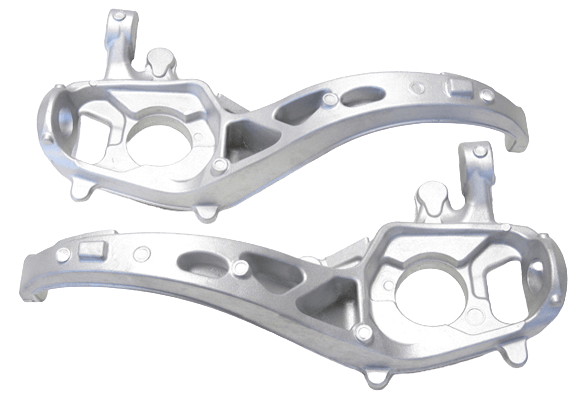

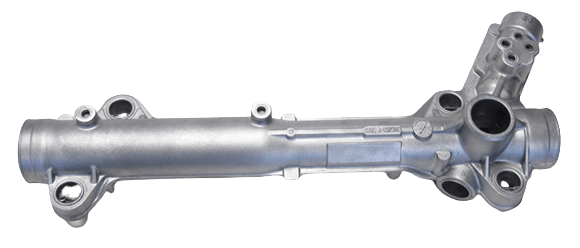

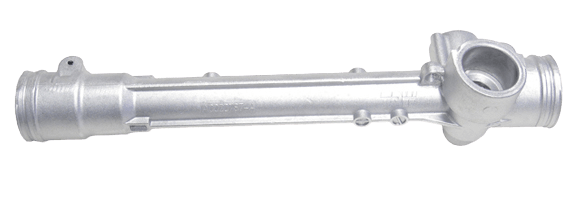

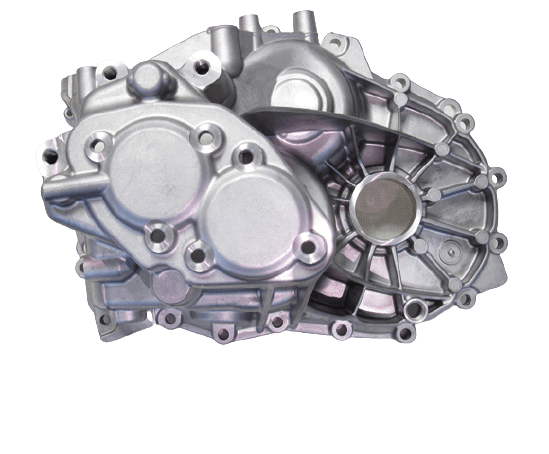

20 years on, the company supplies parts to the UK, Europe, Canada, and Mexico. We have grown from die casting aluminium parts only to supplying a range of products (using high pressure die casting, squeeze die casting, and machining). We can supply aluminium components as cast, cast & machined, or assembled & tested according to the needs of our customers.

90% of all our production is for export, with our components going into vehicles produced by VAG, BMW, Ford, General Motors, Fiat, Renault, Porsche, Mercedes, Jaguar Land Rover, AML and other prestigious marques, as well as non-automotive customers.

Ongoing investment

Over the past 9 years the Company has invested heavily in the development of new products, processes, and capabilities. In addition, through our own investigation and expertise, we have been able to bring several process solutions to bear in meeting world class quality standards. Key to this is our “Forward Focus” ethos which drives change as our customers’ needs grow to meet the new challenges of Electric Vehicle (EV) and Low Carbon Vehicle (LCV) technology.

Our investment & understanding of Additive Material Technology to aid with conformal cooling has allowed us to change what is viewed as feasible within our industry. Consequently, we now have a wealth of experience and data to support the development of lightweight casting technology without sacrificing properties or durability.

High Pressure Diecasting

Squeeze Casting

Machining

X-Ray

We have eleven fully-automated high pressure diecasting cells in the range of 1,000 – 2,000 tonne locking-force. Each cell has its own integral bulk-melting tower furnace to ensure that the correct quantity and quality of metal is always on hand. We are also the only foundry in the UK and Europe to successfully operate a Squeeze casting resource. We have three Squeeze die casting cells ranging from 1450 to 2000 tonnes. These also allow a shot weight of up to 20 kilos.

In 2009, we began developing a dedicated machine shop within the existing Welshpool, UK facility to provide a full-service to new and existing customers alike. In addition, we have a number of secondary processes including sandblasting and x-ray. Subsequently, this enables us to provide a complete customer service.