Our Components

We are an industry leading provider of die cast and machined components. Our engineering expertise has allowed us to refine our processes and manufacture castings that have previously been considered impossible to make. And whilst our core business continues to be of high value to automotive customers, our skills and capabilities are increasingly lending themselves to other sectors as well.

We’re proud to have contributed to the UK’s manufacturing heritage for over twenty years. We have a proven track record in producing die cast and machined components of the highest quality. Our constant drive to implement new innovations to aluminium die casting, machining, and secondary operations has ensured that we continue to hold our place as a trusted supplier.

Die Cast and Machined Components

We’ve been privileged to work with dozens of customers in the UK, Europe, and the Americas on die cast and machined components, made here in the UK on our Buhler Prince high pressure and squeeze die casting machines. This selection of parts represents many of our core capabilities and expertise.

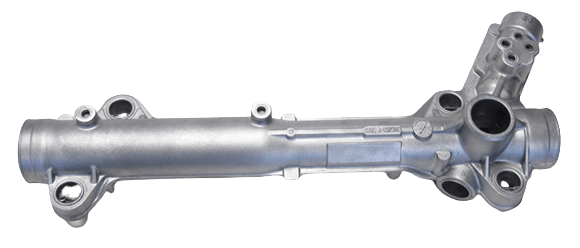

Hydraulic Steering Gear Housings

Since 2001, the Welshpool site has produced over ten million hydraulic steering gear housings, using our enhanced High Pressure Die Casting (HPDC) process. These complex housings need to be of an extremely high integrity and leak-free after extensive machining.

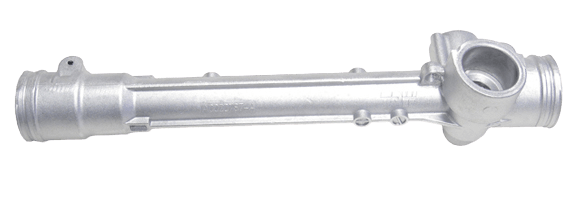

Mechanical Steering Gear Housings

Since 2007, we have seen a significant shift to Mechanical from Hydraulic steering gear systems. This shift has largely taken place in the smaller cars segments, such as the Fiat 500 and Ford KA. CastAlum has embraced this movement and now produces 700,000 gear housings per year for this market. As with the traditional Hydraulic Gear Housings, these parts are produced by our vacuum-assisted High Pressure Diecasting Process.

EPAS (Electronically Power Assisted Steering) Gear Housings

Whereas the small car sector has turned to mechanical steering gears, the large car sectors and the higher-performance sectors have turned to EPAS. CastAlum secured major contracts for the supply of EPAS housings at annual volumes in excess of 600,000 housings per year. These die cast and machined components have been supplied from the CastAlum foundry and machining centre in Welshpool, UK.

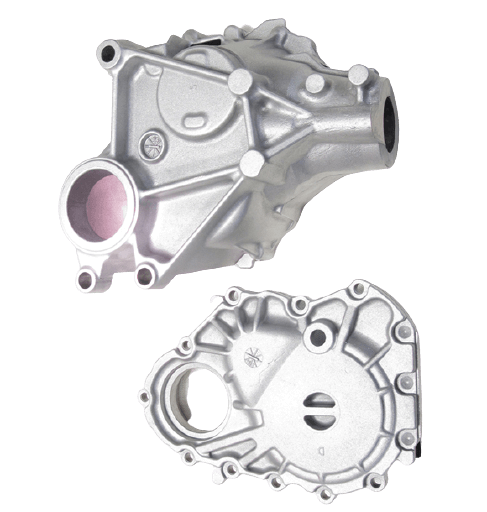

Power Take-Off Units (PTU’s)

CastAlum produces in excess of 250,000 sets of PTU castings per year, using the indirect squeeze casting process . Each set consists of a case and cover casting. These together house the drive mechanisms for 4-wheel drive mode in on-road and off-road vehicles.

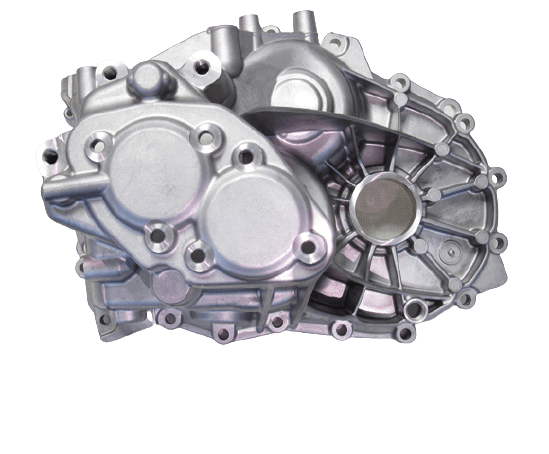

Transmission Cases

In 2009, Castalum invested in a 1600 tonne High Pressure Die Casting cell and CNC machining centres for the manufacture of transmission cases at an annual volume of 200,000 per year. This is another example of die cast and machined components experiencing the benefit of being manufactured by one single supplier right here in the UK.

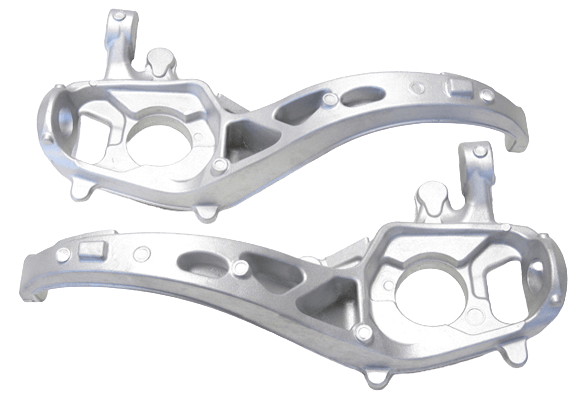

Steering & Suspension Knuckles

CastAlum manufactures aluminium steering and suspension knuckles for high-performance vehicles. Traditionally these parts were cast or forged in iron or steel, for the strength and durability that is required. However, our Squeeze Cast process is able to meet all of the demanding property requirements for these components. All the while we maintain the design flexibility and weight-saving benefits of an aluminium casting.

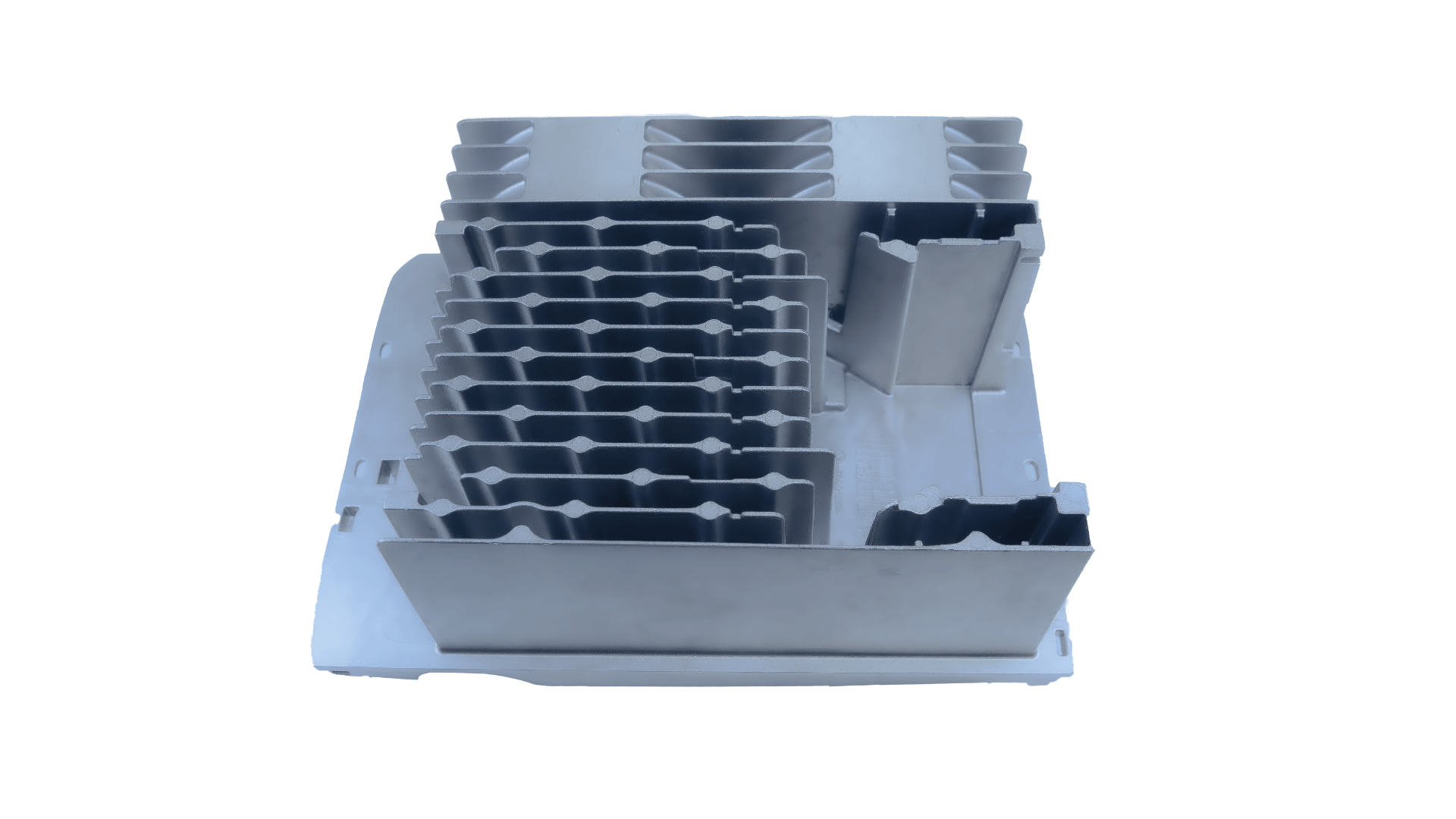

Non-Automotive Die Cast and Machined Components

Apart from our work in the automotive industry, our manufacturing expertise has proved itself useful in other applications and industries as well. We have provided feasibility consultations and produced parts for several leading UK brands. Many of these go on to take advantage of the in-house engineering skills we combine with our casting, machining, and secondary operations.